Vehicle manufacturing

Requirements

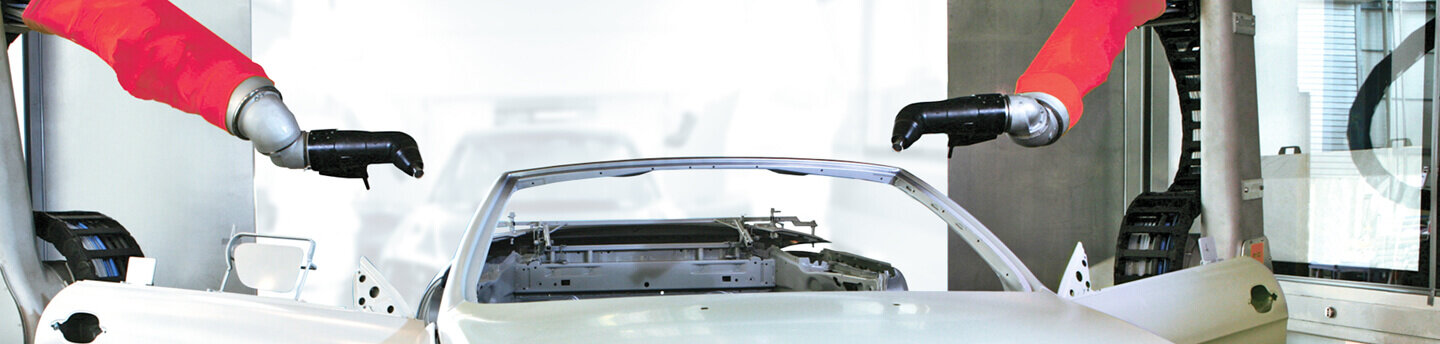

Demanding, innovative, individual: Measurement technology in vehicle manufacturing is subject to particularly high demands in terms of precision and innovation. This is because vehicle manufacturing and robotics are undergoing constant and radical changes: From technologies of the future and emission-free drives (through bio-fuels, synthetic fuels, hydrogen) to digitisation, new standards in quality assurance and customer-specific solutions, for example in the production of wings in aircraft construction.

The Labom solution

Labom takes the high demands placed on the sector into account. Our differential pressure measuring devices, for example for air filter systems, are characterised by their high reliability. We also offer reliable and precise measurement technology with excellent cleanability for tough, sticky or oily and coloured media, such as in paint shops.

Our measuring devices are free of substances that can damage paint (silicone-free) and explosion-proof for flammable media (ATEX). and they are suitable for the use of hydrogen – and can therefore be used in future-oriented technologies, such as the equipment for hydrogen trains.

Applications

- Refuelling facilities airport

- Brake tester

- Dosing station

- Extinguishing equipment airport

- Oil cooling

- Feeder for equipment for gluing/varnishing